Love cookies and cream? Learn more about the main fat component of the cream filling

Have you started your festive cookie baking yet? One of the most popular cookies that occupy a significant place in the world market for biscuits is sandwich cookies. The cream sandwiched between the crunchy cookies or the wafer sheets, enhanced the deliciousness of the cookies and wafers. Chocolate or other coatings enrobed the cookies create mouth-watering desserts that are well worth leaving room for!

Have you ever wonder what are the ingredients in cream fillings? Essentially, the cream filling contains sugar, fat and flavouring. Fat is the most important component in cream fillings and is carefully selected to provide the cream specific characteristics. The characteristics that cream fillings should have are as follows:

- Quick setting (fast rate of solidification)

- Firm at usage temperature and no leaking out from the sandwich

- Good melting properties in the mouth to avoid waxiness

- Free of trans-fats

- Bland in taste to facilitate the addition of flavourings

The cream flavours are vary from indulgent flavours such as vanilla, chocolate and hazelnut to fruity flavours.

Palm oil is the preferred fat for cream fillings formulations basically due to its ability to provide all the above characteristics that are required to produce a good quality cream fillings. If you are concerned about your health, especially the risk of consuming trans-fats and high saturated fat, the palm-based trans-fat free and low saturated fat cream filling is available in the market. Palm-based cream fillings possess the following characteristics:

- The cream is smooth and creamy

- Solidifies sufficiently as it contains sufficient solid fat

- Stay firm at room temperature and able to hold biscuits together

- Quickly melts in the mouth leaving no waxy after taste

Palm oil is a source of natural fat

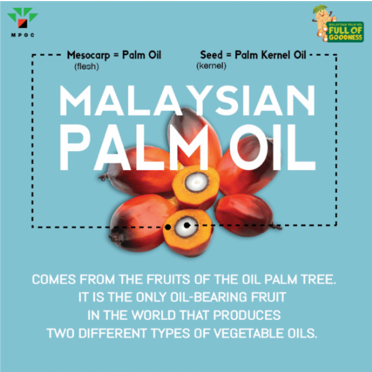

Palm oil is extracted from the flesh (mesocarp) of oil palm fruits and has a balance fat content of 50% solid fat and 50% liquid oil. Various trans-free fats can be derived from palm oil through physical fractionation, without the need to undergo a hardening process using hydrogen called hydrogenation. Besides cream fillings, palm fats are also suitable for use as a milk fat replacer in ice cream mix, caramels and toffees. Picture below shows the applications of various palm fats in food and nutraceutical products.

Processing and uses of palm oil after crude palm oil is processed

Palm oil has high oxidative stability

Palm-based cream filling is suitable for long-term storage as palm oil is highly tolerant to oxidation by surrounding air or high temperatures and does not turn rancid easily.

Smooth and creamy

The type of fat crystals present affects the creaming abilities of fats. Beta prime (β’) fat crystals, which are smaller, more stable, and equally distributed, are present in palm oil. This plays a significant role in its creaming property’s perfection.

Stay firm at room temperature and able to hold biscuits together

Solid fat in food plays many important roles such as improve appearance, enhance taste, provide better texture and enhance stability. It was found that palm-based cream is more stable than dairy creams, especially in hot climates. The good proportion of solid fat content in palm oil contributes to the consistency of the creams and does not easily oiling out during storage.

Melts in the mouth leaving no waxy aftertaste

Solid fat that melts entirely near body temperature is required for the use in biscuit cream to keep the cream’s consistency while preventing a waxy aftertaste. The melting temperature of palm-based fat for biscuit cream formulation are around 36oC-39oC which are very close to body temperature.

Does not contain harmful trans-fat

Trans-fat is formed in high concentration during oil hardening process, specifically partial hydrogenation. Partial hydrogenation of oil is done by adding hydrogen molecule to the oil under high temperature condition with the presence of catalyst. This process converted the natural cis-unsaturated form of the oil to an artificialtrans-unsaturated form which turns the oil into solid state without changing its unsaturated fat content. Partial hydrogenated oil became popular in 1950s-1970s as it was believed to be a healthier alternative to high saturated fat vegetable oils and is widely used in food manufacturing. However, by late 20th century, trans-fat from partially hydrogenated oils has been discovered to have a more deleterious impacts on health than saturated fats, notably heart health, according to a large body of scientific research. Since then, numerous initiatives to reduce artificial trans-fat intake have been taken by health organisations across the world.

On the other hand, palm oil is modified using fractionation controlled by crystallisation (reduced temperature gradually to allow it solidify) and followed by physical separation using filtration. Two types of fats are obtained from this process namely, palm olein (liquid part) and palm stearin (solid part). These fat products can be further fractionated to produce even more fractions and are free of trans-fat. Palm oil is available in different fractions and characteristics, thus is versatile and diverse in its applications.

Sustainable source

The palm oil industry is one of the most highly regulated agricultural sectors in the world. For instance, Malaysia’s palm oil sector ensures compliance with policies that prohibited deforestation, peat development, and exploitation. In Malaysia, oil palm is planted on legal agricultural land. Through the national standard, Malaysian Sustainable Palm Oil Certification Standard (MSPO), Malaysia promotes the expansion of the sustainable palm oil industry. The MSPO certification standard promotes sustainable palm oil production while balancing the need for wildlife conservation, environmental protection, and the livelihood of oil palm-dependent populations.