The Russian Cattle Industry

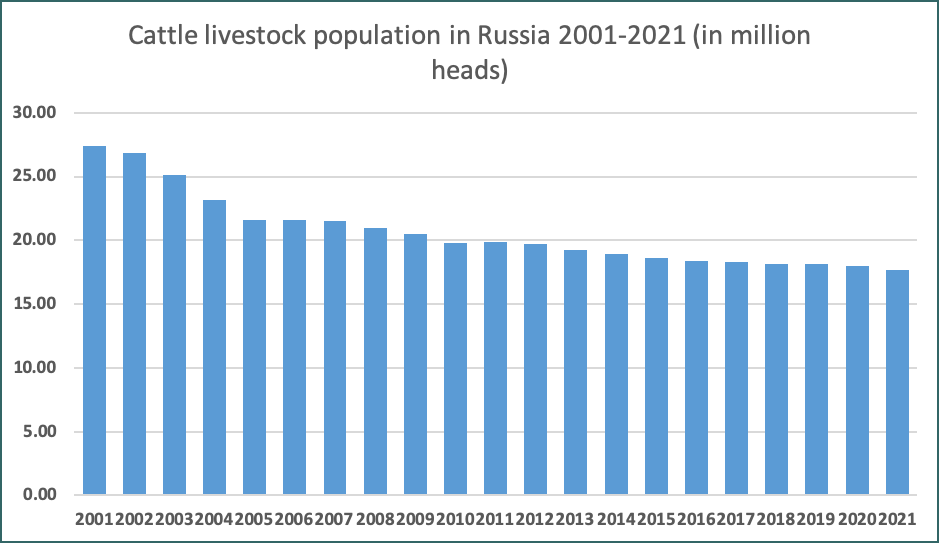

In 2021, the cattle population in Russia amounted to 17.65 million, a decline by 35.5% as compared to its 2021population. The decline was caused by, among other reasons, the high costs of cattle production, vastly attributed to the sourcing of its feed.

(Source: Statista)

Since 2014, Russia has embarked on a campaign of self-sufficiency. With the cattle and dairy industry being one of the most valuable industries in Russia, a special focus was given by the government to develop these sectors. The demand for feed has been rising because of the increasing number of facilities for meat and other production; and to maintain the quality of the animal products breeders use feeds to meet the dietary requirements of their livestock.

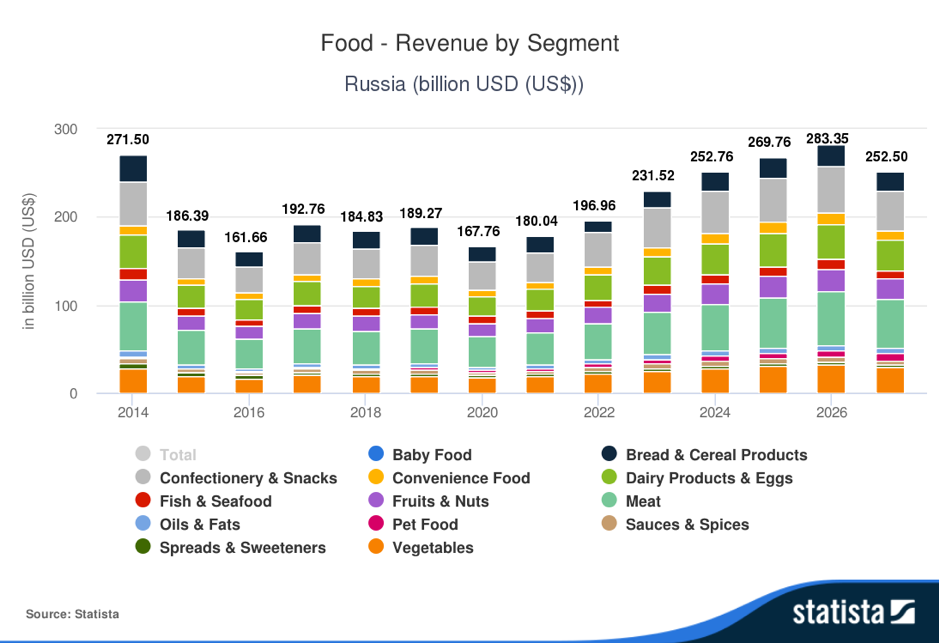

In 2022, cattle-based industries (meat, dairy products and eggs) in Russia is estimated to contribute 36% of the Russian food segment revenues, with an estimated contribution of US$70.65 billion. By 2027, it is estimated that the industry would contribute US$91 billion to the country in food revenue. Growing consumption of meat and other end products such as milk and eggs across the country due to increasing disposable income is considered as one of the prime factors driving the growth of the market. Russia holds a significant share in global animal feed production, and the increasing consumption of meat in the country is set to drive the animal feed market in the coming years.

Potential Applications for Palm in the Russian Animal Feed Industry

Palm Kernel Expeller (PKE)

PKE is very suitable for feeding dairy cows, as the table of composition shows:

| PKE Nutrient | Content |

|---|---|

| Dry matter | 90% |

| Energy | 10.5-12.5 MJ/kg DM |

| Fibre | 60-65% NDF |

| Oil | 8-10% |

| Ash | 4.1% |

| Calcium | 0.45% |

| Phosphorus | 0.6% |

| Magnesium | 0.3% |

| Sulphur | 0.2% |

| Sodium | 0.009% |

| Copper | 24ppm |

| Zinc | 42ppm |

| Manganese | 224ppm |

| Molybdenum | 0.3ppm |

| Cobalt | Nil |

| Starch/sugars | 0.3% |

Source: (Dias F. N. 2010)

At 10.5-12.5 Mega Joules/kg dry matter, PKE is comparable to energy obtained from cereal grains. PKE fibre is highly digestible, as 60% of it is digested within 30 hours. Hence the cow receives nutritional benefits even from the fibre. The fibre encourages acetic and butyric acid production, which helps with milk fat production. A cow should also eat feed that has long fibres such as grass and hay, to ensure good rumination.

Increasing Trend on Bypass Fat Applications and Production Capacities

The modern dairy cow has the ability to produce tremendous volumes of milk and milk components, such as milk protein and milk fat. With increased production potential, there is a much higher energy demand in order for the cow to reach its maximum potential. As a result, in many cases, supplementary fat to the ration can help cover the increased needs, and Palm Fat is finding a foundation role in supporting milk and milk fat production levels.

Yet, the results from the feeding of Palm Fat to dairy cows is rewarding. Fat is the most energy-dense nutrient available, containing almost four times the energy value of carbohydrate. It is a well-known fact that long chain fatty acids such as C16:0 and C18:0, found in palm fats, are the most influential ingredient affecting lactation efficiency, as their incorporation into milk butterfat is more efficient than even milk fat synthesis in the udder.

Due to the high melting point of palm fats, they are able to bypass the rumen and be absorbed in the small intestine. This bypass fat allows the cow to benefit from the fatty acids, instead of it degrading in the rumen and depressing fibre digestion.

It is estimated that Russia imports a total of 20,000 metric tonnes (MT) of bypass fat, with local production capacity at 20,000 MT annually. Several key Russian market players such as Kempartners Ltd, Prodinvest Group, Vlasagro Company, EFKO, and Rusagro are increasing their bypass fat production capacities. Taking into account the current economic efficiency, bypass fat has the potential maximum market size of 100,000 MT.

Prepared by Fazari Radzi andAleksey Udovenko

*Disclaimer: This document has been prepared based on information from sources believed to be reliable but we do not make any representations as to its accuracy. This document is for information only and opinion expressed may be subject to change without notice and we will not accept any responsibility and shall not be held responsible for any loss or damage arising from or in respect of any use or misuse or reliance on the contents. We reserve our right to delete or edit any information on this site at any time at our absolute discretion without giving any prior notice.